Auto Duct Production Line 2 Performance Features:

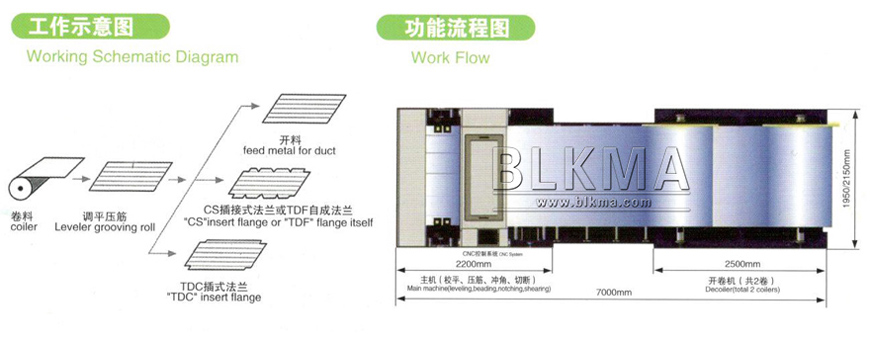

The auto duct production line 2 machine can be used to feed material for HVAC duct manufacturer. Meanwhile, it can feed sheet metal for TDF flange. The functions mainly include leveling, grooving, notching, and cutting. This machine can be used with TDF flange forming machine, Pittsburgh lock forming machine, folding machine, and corner machine together. Adopted aluminum alloy suspension arm, the machine is more easy to operate. The built-in control cabinet reduces wiring as the whole structure and makes it convenient to move. Imported configuration is very stable and convenient to use. The imported equipment includes Japan Mitsubishi CNC system, Schneider electrical system, Beijing Huade and Taiwan hydraulic system and Japan Omron encoder. Besides, basic configuration includes one electric coil rack 2 material trays, a set of leveling and beading equipment, the hydraulic angle-notching machine with four sets of molds, hydraulic shearing machine and a set of CNC control system and software. We can also provide customers 2 material racks (4 material coil) in accordance with different requirements. We have both CNC HVAC duct production line which can make ventilation air duct automatically and separate machines which are easier to move and more convenient to operate. For the auto duct line 2 machine, it's very easy to operate because it's usually used to finish leveling, beading, notching and shearing 4 steps. But the machine is also suitable for upgrading to auto duct line 4 and auto duct line 5 in the future. It will be more saving cost, improving efficiency and saving labor. About after-sales service, we have professional technicians who can teach you how to operate machines by video and we can also provide engineer overseas service or you can send your workers to our factory in China to learn operation method.

Auto Duct Production Line 2 Main import Configuration:

-

Japan Mitsubishi CNC control system+Schneider electrical system

-

Beijing Huade or hydraulic system from Taiwan

-

Japan Omron encoder

Auto Duct Production Line 2 Basic Configuration:

-

One electric coil cradle (two material trays)

-

One set leveling and beading equipment

-

Hydraulic angle-shearing machine with four sets of die

-

Hydraulic sheet-shearing machine

-

A set of CNC computer control system and production software

Auto Duct Production Line 2 Main Technical Parameters:

|

Model

|

Sheeting thickness

(mm)

|

Max Width

(mm)

|

Max working speed

(m/min)

|

max weight of sending coil

(T)

|

Dimensions

|

Power (KW)

|

Weight (T)

|

|

|

|

|

|

|

L*W*H

|

|

|

|

ADL-2-1300

|

0.5-1.2

|

1300

|

15

|

7

|

1900*1950*1500

2500*1950*1600

|

7

|

3

|

|

ADL-2-1500

|

0.5-1.2

|

1500

|

15

|

7

|

1900*2150*1500

2500*2150*1600

|

8.5

|

3.2

|

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay