Spiral Duct Forming Machine Performance Features:

|

Model

|

Diameter range

|

Thickness range(mm)

|

Width(mm)

|

Feeding speed(m/min)

|

Power(kw)

|

Weight(kg)

|

Dimensions(mm)

L*W*H

|

|

BAL-1500

|

100~1500

|

0.5~1.2

|

137

|

0~35

|

16

|

2000

|

3900*3550*1800

|

|

BAL-1500C

|

80~1500

|

0.4~1.2

|

137~140

|

1~45

|

9.5

|

2200

|

2700*1700*2300

|

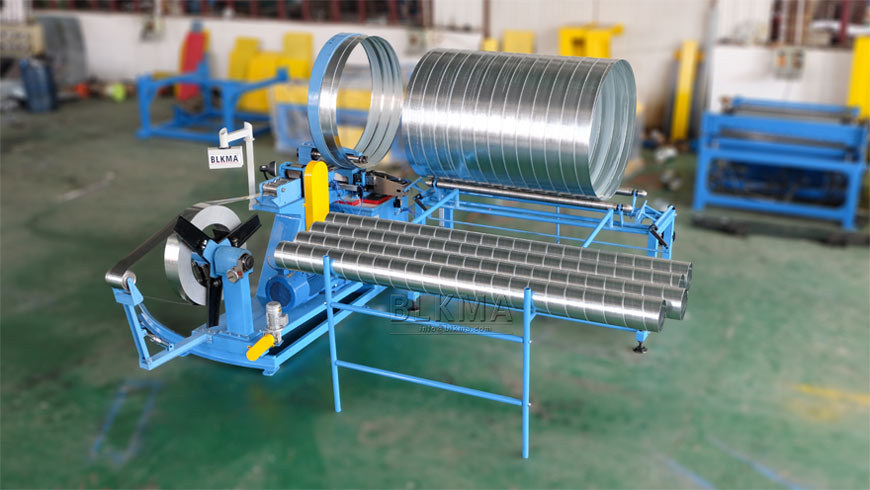

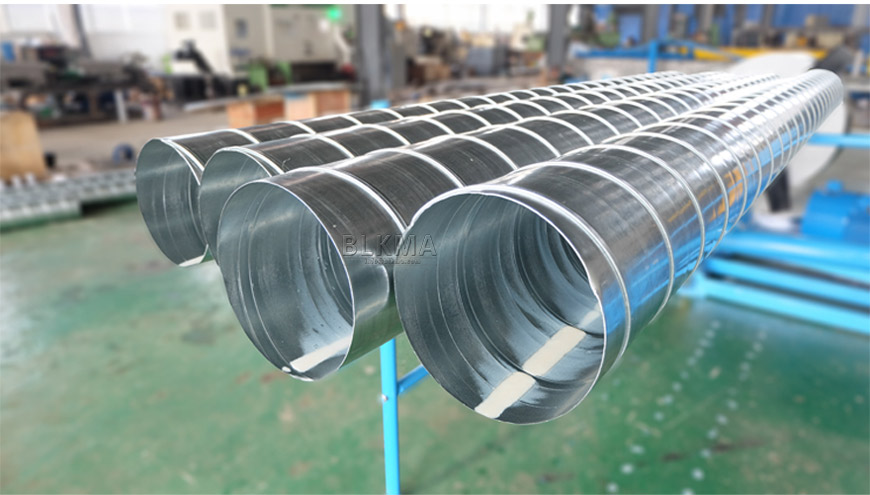

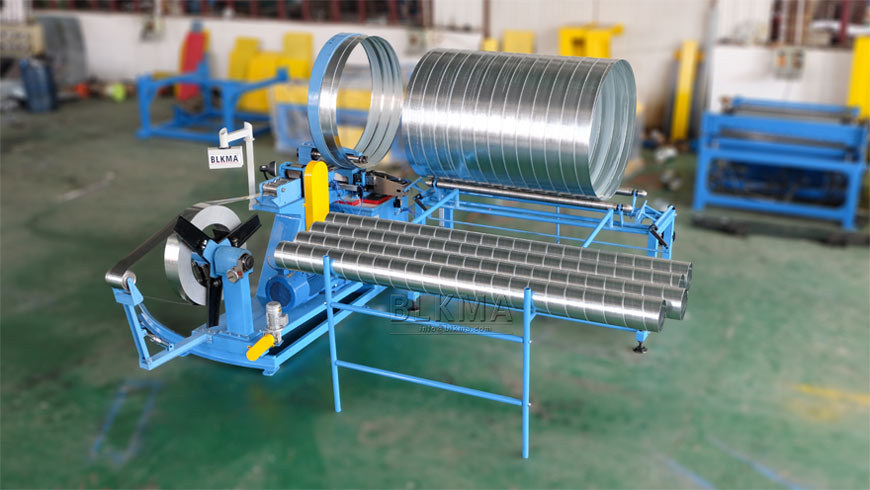

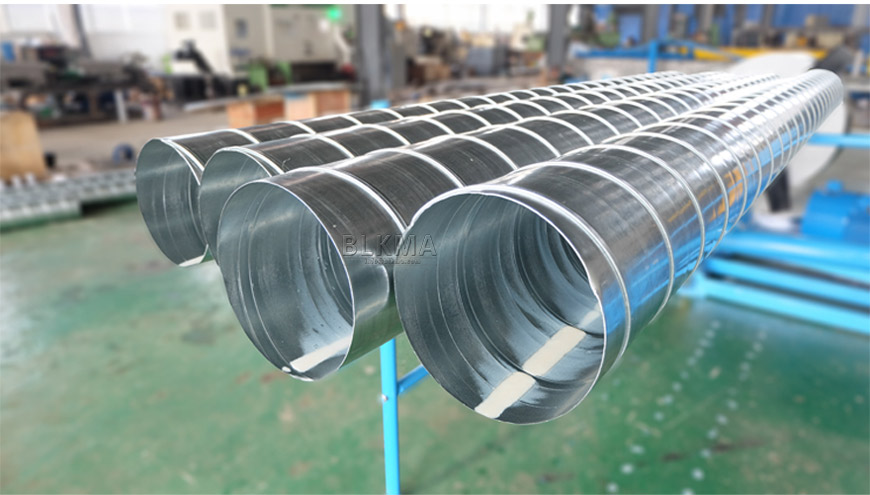

In a given processing of the diameter of the spiral duct diameter scope, the need for pipe die, using different lengths of steel belt, through the proper installation and debugging steel band instead of pipe die. The diameter of the product determines the speed of production, the smaller the diameter, the faster the production speed, on the contrary, the larger the diameter, the slower the production speed, because of the large diameter of the spiral duct, the load on the machine is higher. The length and can be used according to demand, and high-speed synchronous automatic cutting system for cutting. Due to the aesthetic appearance of this duct, this machine has also received considerable attention and many customers have given such machines a high rating. The spiral air duct forming machine is mainly used for making round spiral air duct. The machine can automatically complete round spiral tube with different diameters and different lengths based on customers demand. BLKMA company adopts the principle of using duct mold to form the spiral duct. Spiral duct machine is easy to operate and fast to form duct with accurate diameter. The spiral duct forming machine needs to be used with round elbow machine, angle steel round rolling machine and etc, to complete the other work steps needed in spiral duct processing, BLKMA company produces spiral duct forming machine and round elbow machine, angle steel round rolling machine and other equipment with high quality, also ensure that the pipe size processed out of precise appearance beautiful. So it can effectively help customers greatly improve the competitiveness of their products, Spiral duct machine has always been the most important equipment for round spiral duct. In order to make our products more competitive, we have optimized the structure of the machine for many times to make our machine has been greatly improved in speed and molding effect, and it has won unanimous praise from customers all over the world.

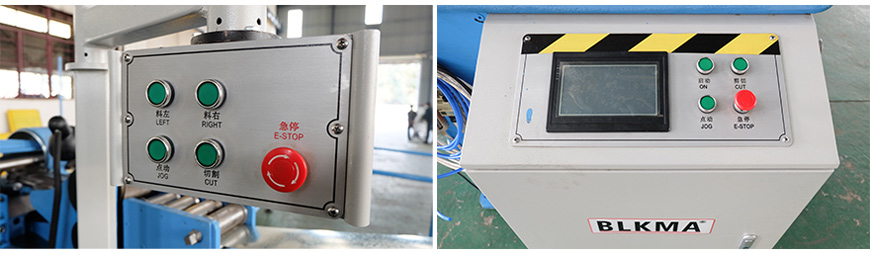

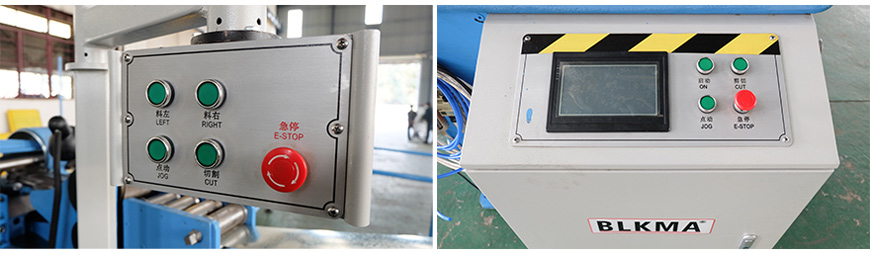

Spiral Duct Forming Machine Main Import Configuration:

-

Siemens control system from Germany

-

Schneider electric system from Germany

-

"FESTO" cylinder from Germany

-

Hydraulic system from Beijing huade

-

OMRON encoder from Japan

Spiral Duct Forming Machine Basic Configuration:

-

One motor

-

One electronic box

-

One electric coil cradles

-

One material trays

-

One Cutting die

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay