Performance features of Auto Duct Production Line 3:

|

Model

|

Sheet thickness(mm)

|

Max width(mm)

|

Max working speed(m/min)

|

Max weight of coil(T)

|

Dimension(mm)

L*W*H

|

Power(kw)

|

Weight(kg)

|

|

ADL-III-1300

|

0.5~1.2

|

1300

|

15

|

7

|

5500*1950*1350

|

7.5

|

3.5

|

|

ADL-III-1500

|

0.5~1.2

|

1500

|

15

|

7

|

5500*2150*1350

|

7.5

|

4

|

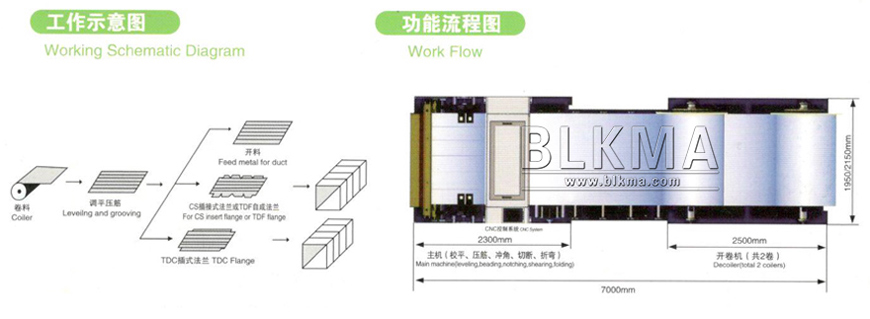

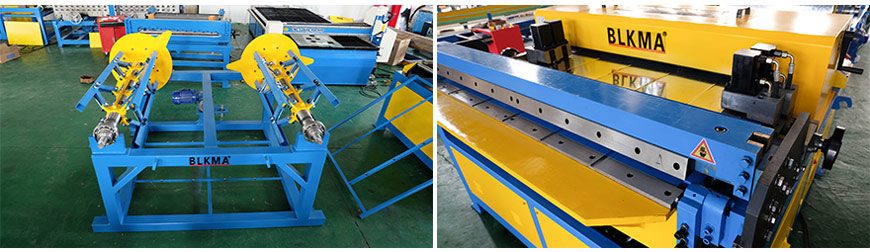

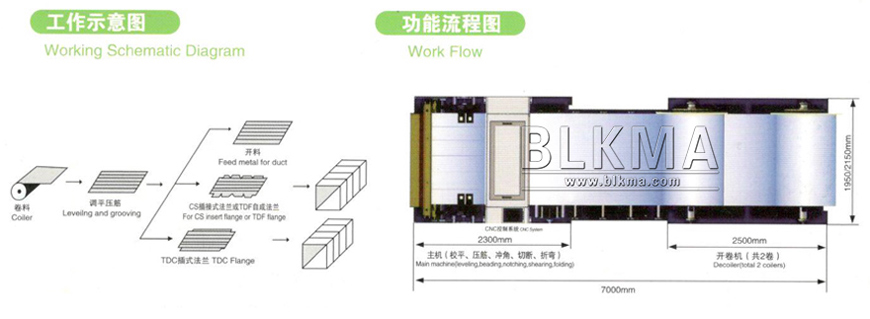

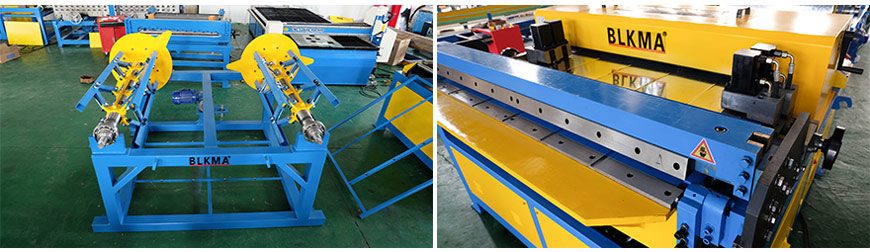

Auto duct production line 3 composed of a decoiler, leveler grooving unit, "V" and "square" notching unit, cutting unit, bending unit composition. The standard configuration the "V" and "square" notching unit make for TDF flange duct, there into the "square" notching unit also can be used to produce TDC flange. Bending unit can be made with the Pittsburgh match the right angle, also can be sheet metal bending into a "square" or "L" type. Greatly improve the utilization of the plate, reduce labor intensity and reduce labor. The production line electrical control part adopts full servo control; the control system has a closed-loop feedback system, Accuracy and stability were obvious improved. The maximum operating speed of 16m/min. Length tolerance is ±0.5mm; diagonal tolerance is ±0.8mm. The system can meet each shift(8 hours) production capacity of the 1000m² duct. As one of leading China auto duct line manufacturers, BLKMA company specializes in manufacturing and sales of air duct line II, III, IV, V, CNC angle steel flange production line, shear, folding, machine, bender, duct zipper, spiral former, CNC plasma cutter, elbow maker, TDF flange machine, grooving machine, slip roller machine and so on. Duct production line 3 can drive blanking for the duct. Meantime, It's very suitable for diversified production like TDF/angle steel/inserted flange forming, the angle steel flange, and inserted flange can be bent into square-shaped pipe automatically.

1. Aluminum alloy suspension arm makes the machine easy to operate.

2. The built-in control cabinet reduces wiring as a whole structure and makes it easy to move.

3. The imported configuration is very stable and comfortable to use. Cnc air duct production line is a duct making line with the highest automation and highest efficiency in rectangular air duct production line machines. The air duct production line machine made by BLKMA - one of reliable

China auto duct line manufacturers can help customers to finish all needed process from cutting sheet metal to forming the whole duct under the control of auto CNC system. Automatic CNC control system greatly improves the precision and the beauty. Auto duct production line includes auto duct line 2, auto duct line 3, auto duct line 4, linear auto duct line 5 and U shape auto duct line 5. Our company will provide customers the most suitable machines according to customers needs. Besides, we can also customize machines on the basis of your special requirement.

The basic configuration of Auto Duct Production Line 3:

-

One electric coil cradle(two material trays).

-

One set leveling and beading equipment.

-

the hydraulic angle-shearing machine with four sets of the die.

-

The hydraulic sheet-shearing machine, hydraulic bending machine, hydraulic press machine.

-

A set of CNC computer control system and production software.

-

One motor

The main imported configuration of Auto Duct Production Line 3:

-

Beijing Huade+Hydraulic system from Taiwan.

-

Japan Omron encoder.

-

Japan Mitsubishi CNC system

-

Germany Schneider electrical system.

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay