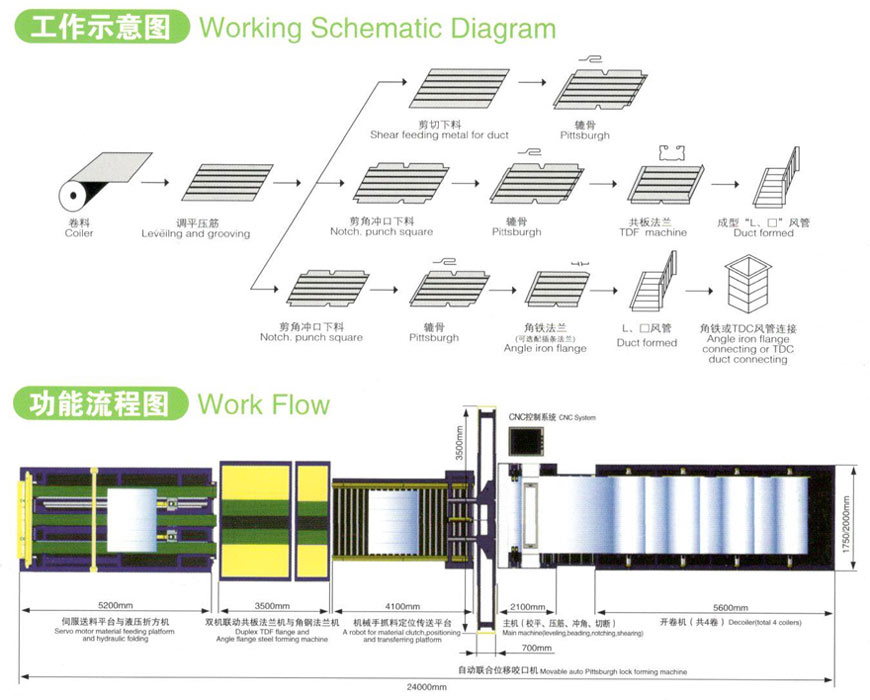

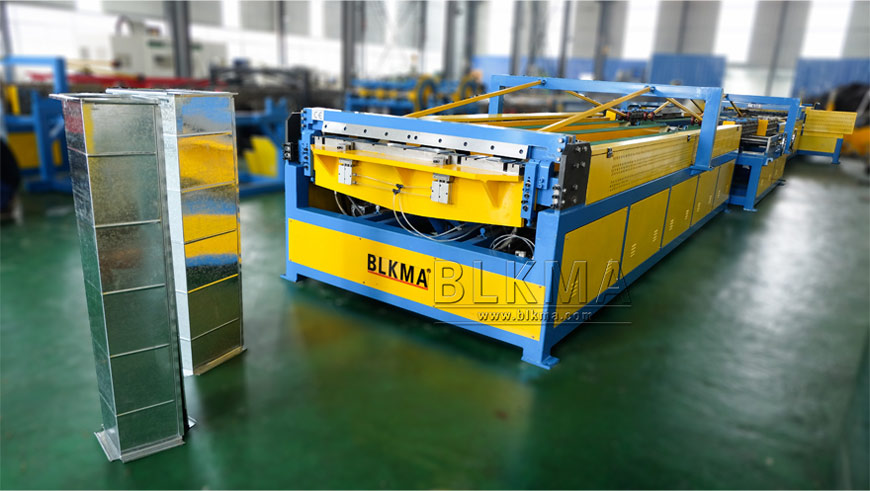

It's mainly for TDF / angle steel / C-shaped flange forming with daily processing capability of 600-2000 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling, leveling,beading, punching, shearing, locking, forming TDF / angle steel / C-shaped flange and folding.

|

Cylinder imported from Germany Festo |

|

Mitsubishi CNC control system |

|

Japan Omron encoder |

|

Taiwan Hiwin linear guideways |

|

Schneider electrical system |

|

Two electric coil cradles, 4 material trays (5-7t each roll) |

|

One rack |

|

One host (line 2 host) |

|

One mechanical arm clutching, locating and transferring plateform |

|

One displacement type locking machine |

|

One duplex TDF flange forming machine |

|

One duplex angle steel flange forming machine |

|

One servo feeding platform |

|

One hydraulic folding machine |

|

One set of computer controlling system |

|

Model |

Sheeting thickness (mm) |

Max width (mm) |

Max working speed (m/min) |

Max weight of coil (T) |

Dimension (mm) |

Power (kW) |

Weight (T) |

||

|

ADL-5-1300 |

0.5-1.2 |

1300 |

15 |

7 |

24000 |

3500 |

1500 |

30 |

12 |

|

ADL-5-1500 |

0.5-1.2 |

1500 |

15 |

7 |

24000 |

4000 |

1500 |

30 |

13 |

we will contact you within 24 hours.

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay