Model | Pressure(KN) | Dimension of die holder(mm) | Slider stroke | Slider stroke times | Power(kW) | Dimensions(mm) L*W*H |

J23-25T | 250 | 40*60 | 70 | 60 | 2.2 | 1220*920*2060 |

J23-40T | 400 | 50*70 | 100 | 50 | 3 | 1320*970*2380 |

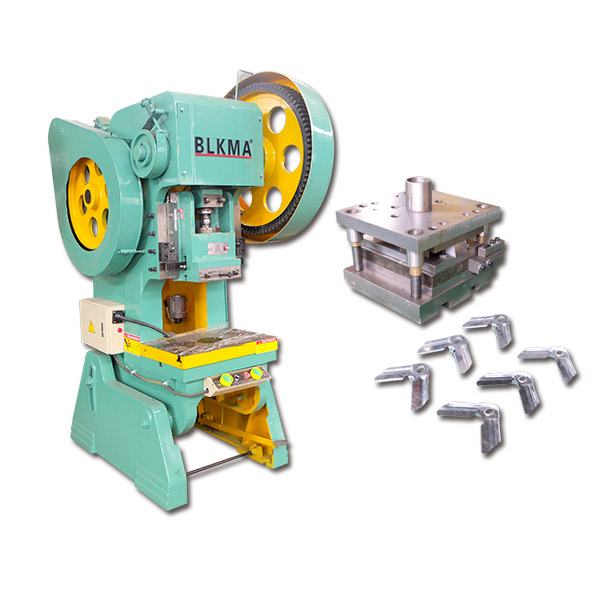

Versatile and Efficient: The J23 series presses, developed by the BLKMA team, represent a new generation of plate processing machines. These presses are designed for cutting, punching, blanking, bending, and light stretching work. They can produce duct corner codes with the die and are also capable of punching and cutting angle steel with relevant dies.

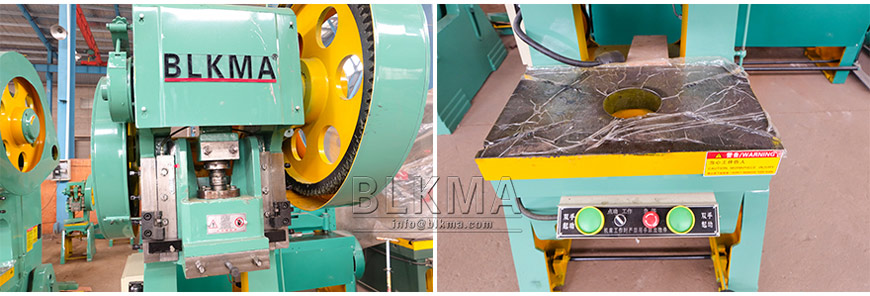

Innovative Design: The new structure design is both economical and practical. The operation space is wide, and the movable bolster can be moved out of the frame to set the die, making the structure simple and aesthetically pleasing. This machine is essential for rectangular duct production.

Professional Guidance and Customization: BLKMA provides expert purchasing advice to help customers choose the right machine, saving costs and improving efficiency. The machines can be customized with the appropriate motor power and voltage to match the customer’s local power environment, ensuring safe and efficient use worldwide.

High-Quality and Reliable: For many years, the duct corner punching machine has been one of the most efficient products in the duct/pipe processing industry. BLKMA offers high-quality duct fabrication equipment to clients around the world, backed by strong technical strength and years of production experience. Various models, such as J23-63T, J23-80T, and J23-100T, are available and can be customized according to customer requirements.

Safety and Ease of Use: Designed for accuracy and stability, the duct corner punching machine is safer and easier to operate. BLKMA’s commitment to meeting customer needs ensures that this machine is a reliable choice for duct manufacturing.

Global Recognition: Known for its excellent product quality, innovative design, reasonable pricing, and superior after-sales service, the BLKMA brand is highly praised by customers both domestically and internationally. The BLKMA brand is the best choice for duct corner punching machines.

One motor

One slider

One punch die

One electronic box

One control electric system

One cylinder

we will contact you within 24 hours.

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay