In the daily use of the

TDF flange forming machine, attention should be paid to maintenance, which is the guarantee of long-term stable and reliable operation of the TDF flange forming machine and is a necessary measure to extend its service life. Attention paid to maintenance can avoid 80% of accidental failure.

The maintenance shall be carried out in accordance with the related instructions in the first level maintenance of the TDF flange forming machine. In many cases, users may take the maintenance of the fuselage of the TDF flange forming machine into account, but ignore the maintenance of accessories.

Here, we also want to remind everyone doing the maintenance of relevant accessories.

TDF flange forming machine accessories can be divided into three types:

1. Auxiliary equipment that is not currently in use.

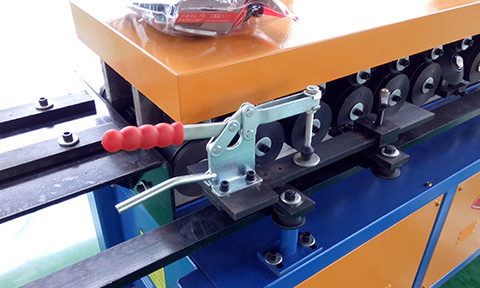

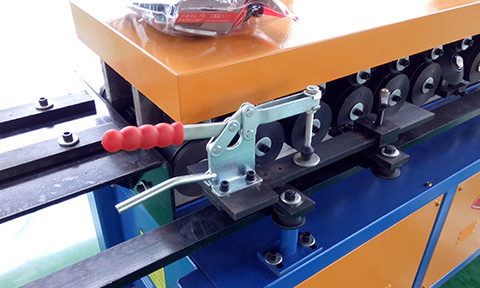

2. The auxiliary devices needed to process different work-pieces, such as clamps, various kinds of knives, and so on.

3. Special tools and spare parts for repair and maintenance.

Specific maintenance measures of TDF flange forming machine parts are as follows:

1. Apply anti-rust oil to common iron parts and wrap them with moisture-proof anti-rust paper.

2. In addition to applying anti-rust oil, large spare parts should be covered with canvas or plastic cloth to achieve the purpose of anti-dust.

3. All pipelines and pipes must be wrapped in plastic cloth to prevent dust and impurity from entering the pipeline, causing the electromagnetic valve or other hydraulic components and pneumatic components to be blocked when used.

4. Prevent direct sunlight, because many electrical spare parts are plastic parts, which will be deformed, brittle and damaged under sunlight.

5. All spare parts must be inspected regularly for rust, dust, and dirt entering to make them dirty. If there is any problem, the spare parts must be descaled, re-greased and repackaged.

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay