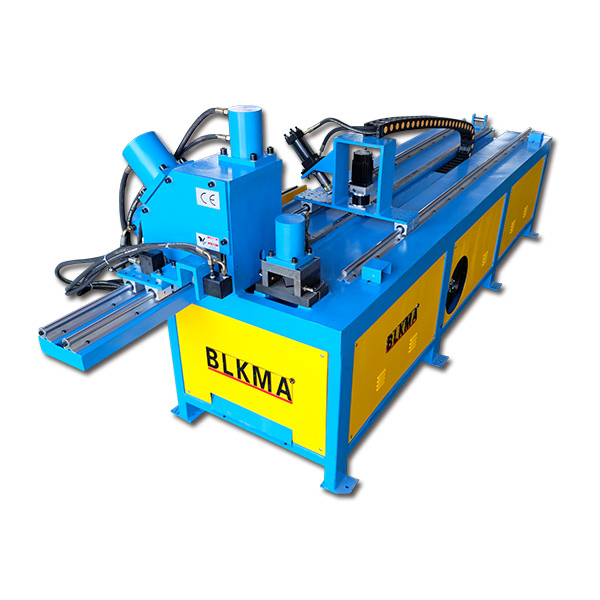

Fully automatic angle steel flange production line, or CNC angle steel flange production line, is mainly for punching and cutting duct angle steel flange. The machine are designed to feed, punch, cut automatically in order to save labor improve efficiency. It's very fast, accurate and highly automatic.

Model | Working range | Dimension(mm) L*W*H | Power(kW) | Weight(kg) |

JG-50 | 30/40/50 angle steel | 3600*1100*1400 | 5 | 900 |

The CNC Angle Steel Production Line is a highly versatile and efficient machine designed for manufacturing angle steel flanges and ducts, equipped with punching and shearing capabilities. It offers flexibility in producing various duct shapes, and its rolling wheels can be adjusted to meet customer specifications.

Key Features:

High-Quality Build: The machine's mechanical gears, shafts, and rolling wheels are made from high-quality steel. They undergo high-frequency carburizing, quenching, and other processes to ensure durability, quality, and mechanical stability.

Versatile Design: This kind of duct fabrication equipment can be customized to produce a variety of duct shapes, and the rolling wheels are adjustable to meet different customer needs.

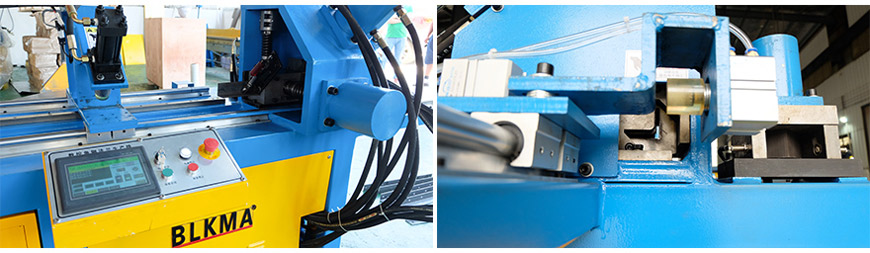

Automatic and Precise: The machine is fully automated, using servo motors for accurate feeding dimensions. It ensures fast and precise punching and cutting of angle steel flanges, improving production efficiency and labor savings.

User-Friendly: Programming is easy, as the machine only requires input for workplace size, hole distance, and the number of holes to be punched. This simple operation enhances user convenience.

Fast Switching: The machine's new design mold allows for angle steel switching within 5 seconds, making it a highly efficient and time-saving solution for production lines.

Perfect Duct Connection: The CNC angle steel production line ensures seamless duct connections, crucial for manufacturing high-quality air ducts. It is an indispensable part of duct production and guarantees a more perfect, reliable connection.

Comprehensive After-Sales Service: We are committed to customer satisfaction and provide 48-hour on-site service to address any concerns.

Global Reach: With CE certification and products exported to Southeast Asia, EU, South America, and the Middle East, BLKMA offers high-quality machinery at competitive prices.

Innovative R&D: Our company has an independent R&D institution, ensuring continuous product innovation and adaptation to market needs.

Reliable Performance: The CNC angle steel production line is recognized for its high automation, precision, and efficiency, making it a trusted solution for duct manufacturing industries worldwide.

Beijing Huade+Hydraulic system from Taiwan.

Japan Omron encoder.

Cutter and punching die which are both made of Japan SKH51.

Servomotor-driven feeding system.

One motor

One electronic box

One electric control system

we will contact you within 24 hours.

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay