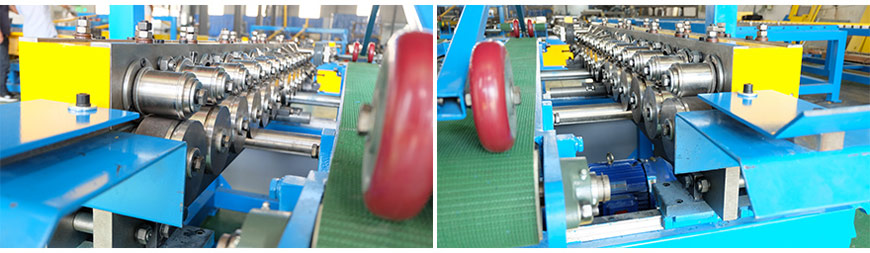

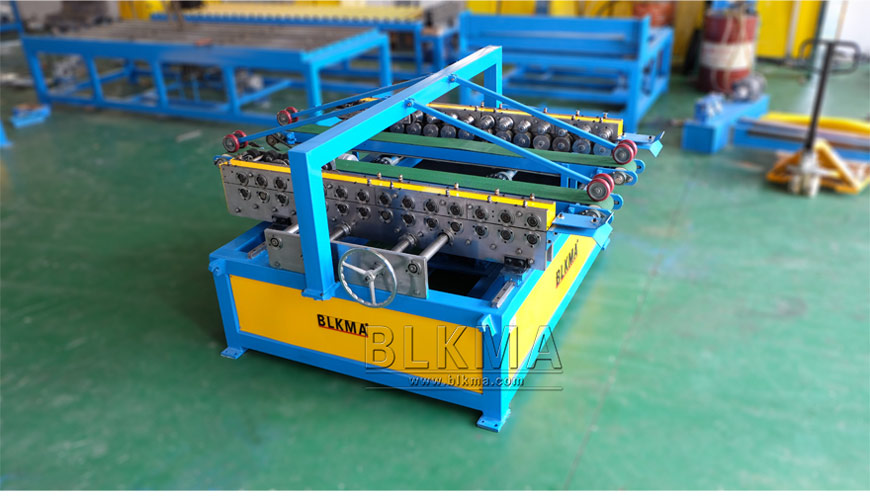

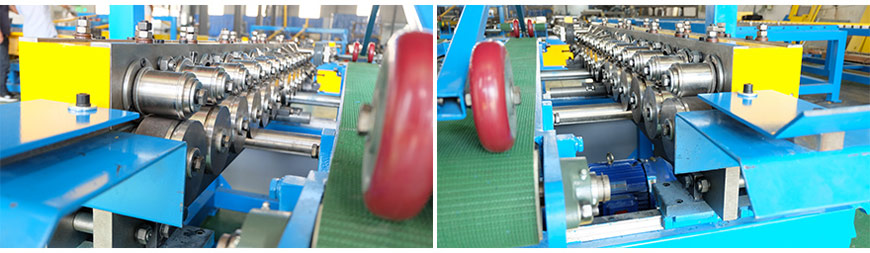

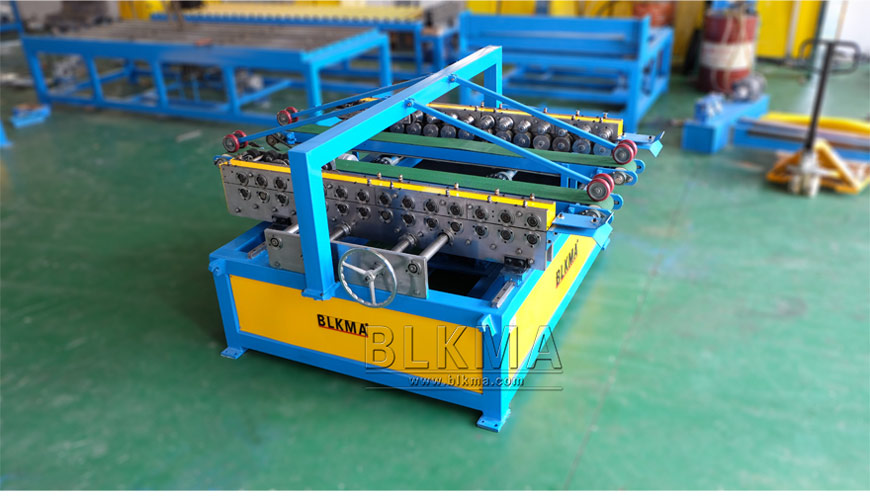

Duplex Flange Forming Machine Technical Performance Feature:

Duplex TDF flange forming machine can form flange shape at two sides of sheet metal simultaneously. The machine adopts double-side drive with Tai wan HWIN linear guide rail to realize high loads and high remove accuracy. What’s more, we can add clip at two sides of the machine according to customers' requirement. Compared with single TDF flange forming machine, the duplex TDF flange forming machine can provide duct processing efficiency and shorten duct making time. It will save labor costs to a large extent. Our company especially launch the machine with GCr15 steel rolling reel. The service life is 5 times than common 45 steel material. Besides, this machine can make stainless steel flange. You can also call it double TDF flange forming machine. As one part of square HVAC duct making machines, the duplex flange forming machine can be used with other square ventilation duct forming machines together to finish a whole duct processing, such as lock forming machine, pneumatic sheet metal folding machine, grooving machine, motor cutting machine, lock seam closing machine, clips cutting machine, etc. We can provide a complete machines series on the basis of different customers requirements and practical operating environment. BLKMA company has both CNC duct production line which can make air duct automatically and separate machines which are easier to move. You can contact us at any time via email, mob, WhatsApp, Skype, facebook, youtube, and WeChat if you have any question about HVAC duct machines. We will reply you and help you to solve all problems as soon as possible. For after-sales service, we have skilled technicians who can teach you how to operate machines via video. Besides, engineer overseas service is available. If you want engineer overseas service, you need to tell our worker especially. We need to check detailed information with you because there are different specifications in the different country.

Duplex Flange Forming Machine Main Technical Parameters:

|

Model

|

Power

(kw)

|

Sheet thickness

(mm)

|

Shape

|

Weight

(kg)

|

Dimension

L*W*H

(mm)

|

|

T-12-2

|

4

|

0.5-1.2

|

|

2100

|

2450*2250*1300

|

|

T-15-2

|

5.5

|

0.8-1.5

|

Call us on:

Call us on:  Email us:

Email us:  Dongcheng Industrial park, Bowang District of

Dongcheng Industrial park, Bowang District of  FREE QUOTE

FREE QUOTE

English

English 한국어

한국어 Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية Polska

Polska Svenska

Svenska українська

українська Malay

Malay